Call it luck, karma or whatever. Late one night I happened to be looking at kz750 engine pics on the net out of boredom. Some how, I noticed a tiny detail in another re-build project. The circle below is where I noticed the difference. On the other project, something was on the shiny metal peg. I knew my engine didn't look like that. After spending so much time on this crankcase, I know it like the back of my hand. Since my case was together, I had to go back and look at some old pics to verify what I had noticed. Sure enough, I never put the chain tensioner guide on! The reason was because this part is in the cam shaft parts diagram. Why would I be looking there when I'm still working on the crankcase?

Oh well. Its a pain in the ass to open it up a second time, but at lease I noticed it when I did.

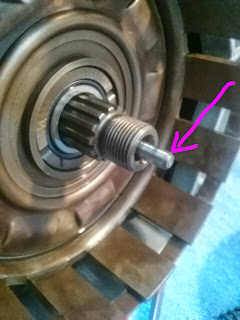

I snapped this after I opened it up (for a second time, mind you). Yep, no cam chain tensioner guide where it should be. Also, notice the nice brown rust on it? It was shiny before. I'll get to that later...

The end circled below fits onto that peg.

There she is, right where she belongs. Now I get to put the transmission in, the crank shaft in, spread liquid gasket around and mate the halves AGAIN. At least its good practice. I can do it with my eyes closed now.